Computerized Shock absorber spring strength tester

Model: STM-MS-20H

Test standards

JB/T 7796 Spring tension and compression testing machine standard,

JJF 1134-2005 Calibration specification for special working measuring machine,

GB/T 13634 Calibration of dynamometers for testing machines.

Introductions

This computer-controlled spring testing machine is a special testing machine designed and manufactured according to the national standards for spring tension and compression testing machines.

It can be used for testing and analysis of tension, pressure, displacement, deformation, stiffness, and free height of various springs.

Features beautiful appearance, reasonable structure, high rigidity and small deformation of the whole machine.

Using the independently developed spring-specific data processing and acquisition system, it is easier to use and smarter

The machine adopts a fully digital speed regulation system with high speed regulation accuracy and stable performance and a precision motor as the drive system, and a multi-channel controller as the core of the control system. The windows-based data processing software realizes real-time display of test force, test force peak value, beam displacement, test deformation and test curve. All test operations can be completed on the computer.

Structure

3.1 Host: This model is different from ordinary tensile testing machines. The mechanical part adopts four-column optical axis and double-screw structure, the whole machine has high rigidity, small deformation, spring hook strength, pressure plate hardness after quenching treatment, tensile strength and compressive hardness are guaranteed,

3.2 Transmission system: It is composed of pulley deceleration system, precision ball screw and guiding optical axis.

3.3 Drive system: The system is driven by precision digital governor and servo motor.

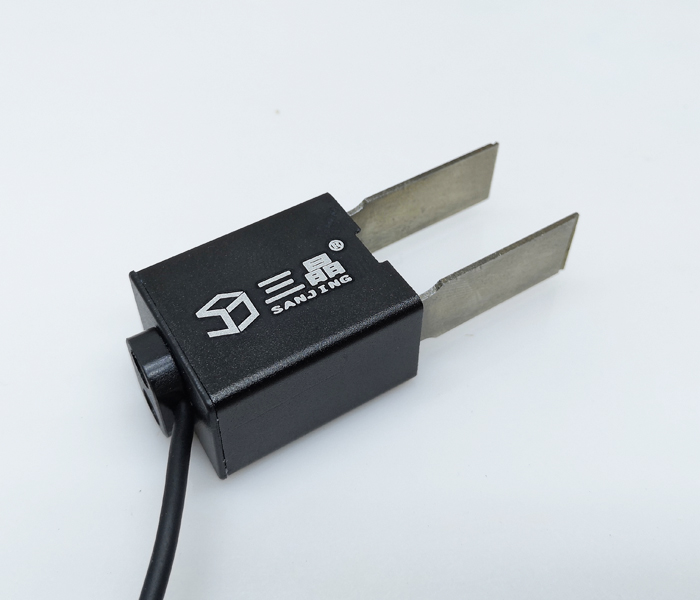

3.4 Measurement control system: The test force measurement control system is composed of high-precision load cells, measurement amplifiers, A/D conversion, and regulated power supply; the displacement measurement control system is composed of photoelectric encoders, frequency multiplier shaping circuits, and counting circuits. Through various signal processing, the functions of computer display, control and data processing are realized.

3.5 Safety protection devices: overload protection, beam limit position protection, overcurrent, overvoltage, overspeed protection, etc.

Specifications

| Maximum test range |

20kN |

| structure |

Four columns, double lead screws |

| Way of working |

Ball screw drive, precision motor loading |

| Display method |

computer control and display |

| data processing |

Automatic collection, processing, can save, query, print |

| range |

0-100% |

| Minimum reading of test force |

0.001kN |

| Test force indication repeatability error |

1.0% |

| Displacement resolution |

0.01mm |

| test space |

500mm |

| Platen diameter |

200mm |

| Platen hardness |

>HRC 55 |

| Parallelism of the upper and lower platens |

≤0.10mm |

| speed range |

0.01-500mm/min |

| Tester size |

600×400×1750mm |

| Testing machine weight (net weight) |

400kg |

| Power supply |

AC 220V±10% 50Hz |

| Protective function |

Program and mechanical double protection |

| noise |

50dB(A) |

| Assembly, Electrical, Appearance |

Comply with national standard GB/T 2611 |

| Packing and shipping |

In line with the Ministry of Machinery standard JB/T 6147 |

| Testing machine level |

Level 1 |

Related Items

Sales01

Sales01

Sales Manager

Sales Manager