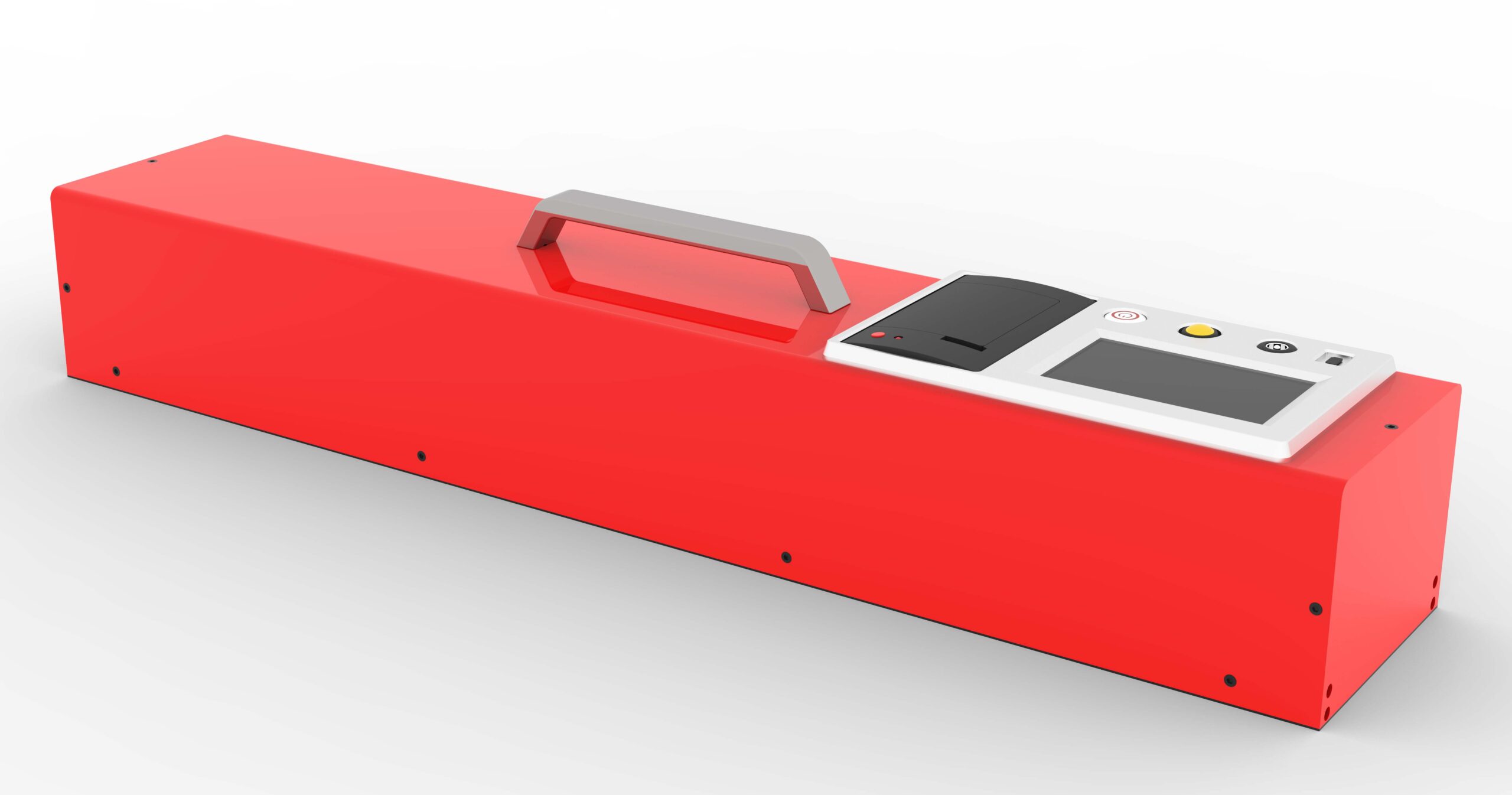

Trailor-mounted Falling Weight Deflectometer FWD SHRP-LTPP

Model: JT-FWD-01

Standards

SHRP-LTPP AASHTO R32 FWD;JTG 3450-2019;T0953-2008; JTT1125-2017;JJG133-2017

Introduction

The Falling Weight Deflectometer (FWD for short) is a special equipment used to evaluate the bearing capacity of pavement. It starts the drop weight device through the computer-controlled hydraulic system, so that the drop weight of a certain mass falls freely from a certain height, and the impact force acts on the bearing plate and transmits it to the road surface, thereby imposing a pulse load on the road surface, resulting in instantaneous deformation of the road surface. Sensors at different distances from the measuring point detect the deformation of the surface of the structural layer, and the recording system transmits the signal to the computer, that is, the dynamic deflection and the deflection basin generated under the action of the dynamic load are measured.

Compared with the traditional Beckman beam measurement deflection, the drop-weight deflection is easy to use, fast, safe, labor-saving, simulates the actual situation to apply dynamic loads, and is suitable for long-distance and continuous measurement. After analysis and comparison, the US Federal Highway Administration confirmed that FWD is a better dynamic load assessment equipment for pavement bearing capacity, and selected FWD as an important equipment for pavement strength assessment in the implementation of SHRP plan.

Features

Easy to set up test parameters, the number of deflection drop weights, the weight lift height and the impact load can be set before the test, which is converted by the built-in load height relationship

The data acquisition software can display the current deflection and load curve of each drop weight in real time; later, the data processing software can be used to view the load and deflection time history curve of the effective drop weight

Hydraulically controlled mechanical locking device for safe detection

Specifications

| Braking device |

Equipped with inertia brake |

|

| Traction device |

Standard trailer coupler with 50mm trailer ball |

|

| Signaling device |

With steering, braking, reversing, width display combination lamps |

|

| GPS function |

With GPS module (can detect positioning) |

|

| Safety warning coating |

Equipped with eye-catching safety warning reflective signs |

|

| Engineering lights |

Equipped with engineering lights |

|

| Hammer lifting method |

Hydraulic lifting hammer |

|

| Power supply |

Tractor charging system provided |

|

| Deflection sensor range |

-3500um~+3500um |

|

| Number of deflection sensors |

Standard 9, 1-23 optional |

|

| Deflection test accuracy |

better than 2% |

|

| Deflection resolution |

0.1um |

|

| Deflection repeatability |

The standard deviation of 40 test data at the same point is not more than 3μm |

|

| Maximum load |

120/150kN (upgradeable to 300kN) |

|

| Load range |

0~120/150kN |

|

| Load accuracy |

1% |

|

| Load resolution |

0.1kN or 1kPa |

|

| Temperature range |

-50~100℃ |

|

| The temperature measurement accuracy should be |

0.5% |

|

| Emergency lifting device |

Equipped with manual hydraulic lifting device |

|

| Temperature resolution |

0.1℃ |

|

| DMI measurement accuracy |

1% |

|

| DMI resolution |

0.1m |

|

| Front distance display |

Real-time display of measuring point spacing |

|

| Test time per point |

15~20s |

|

| Loading disk format |

300mm diameter 4-point sector disc |

|

| Laptop |

Windows7/XP operating system |

|

| Software function |

Calculation with Beckman Beam Data Conversion System

Automatically find the best conversion data

Single point deflection distribution statistics

Calculation and data export representing deflection

data normalization

Evaluation of load transfer ability of joints

Evaluation of plate voids and analysis of stiffness composition

Automatically record the position station of each test point

Temperature correction possible |

|

| Walking speed |

1~140Km/h |

|

| Safety locking mechanism |

Equipped with safety locking mechanism |

|

| Bearing method |

Carrier plate automatic locking mechanism |

|

Related Items

Sales01

Sales01

Sales Manager

Sales Manager