Shock absorber spring fatigue tester

Model: STM-PL-20H

1. Introductions

This machine is mainly suitable for fatigue life test of various helical cylindrical springs, shock absorbers, gas springs, elastomers, elastic elements and other components. This machine has been improved in structure, function and appearance, especially the control system has been comprehensively upgraded, which has improved the convenience and reliability during the test process, and its performance is far ahead of similar products.

2. Features

2.1 The fuselage is made of high-quality thickened steel plate to ensure that the machine will not deform under long-term load;

2.2 The adjustment of the test space adopts electric control, which is convenient and fast;

2.3 The test area is equipped with a transparent visual protection net to ensure the personal safety of the operators;

2.4 The test load adopts domestic high-quality precision servo motor, which has stable output torque performance and reliable operation, and overcomes the influence of load changes on the machine;

2.5 The new lubrication and oil guiding system can realize the filling, automatic collection and reuse of lubricating oil at the test site, which has changed the secondary pollution of the machine caused by the overflow of lubricating oil in the past, and greatly reduced the manual operation (the standard configuration is manual feeding. lubricating oil);

2.6 The control program adopts the integrated design of the whole machine, which is beautiful, safe and easy to control.

3.Features

3.1 The amplitude and frequency can be adjusted according to various non-copper test requirements;

3.2 Industrial-grade touch screen control panel, the number of tests and the frequency can be preset according to the requirements, which can realize the functions of automatic shutdown of the preset number of tests, and the ability to continue the last unfinished test when the machine is turned on;

3.3 The latest touch system test interface refreshes the trend of load changes over time in real time (it’s optional function which need to equip a load sensor);

3.4 The displacement sensor is installed, which can measure the change of sample deformation with the number of tests in real time; the test amplitude can also be calibrated, which can better ensure the accuracy and reliability of the test (this item is optional);

3.5 Break stop function, emergency stop protection function, overcurrent and overvoltage protection function.

4. Specifications

4.1 Maximum test force (N): 20000

4.2 Test longitudinal space (mm): 600 (can be customized)

4.3 Sample platen diameter (mm): 150 (can be customized)

4.4 Adjustable frequency of testing machine: 0~3Hz (180 times/min)

4.5 Test frequency: according to the actual sample

4.6 Maximum deformation (mm): 100

4.7 Counting capacity: 999999999

4.8 Counting stop accuracy: 1

4.9 Test station Single station: according to the size and force of the spring

4.10 Dimensions and weight of the main body of the testing machine: 1300*100*2500mm, 2450kg

4.11 Power supply AC 380V±10% 50Hz

5. Configurations

5.1 Test machine host (including machined parts and 1 set of optical shafts):

5.2 Eccentric wheel loading system: 1 set

5.3 Pulley, V-belt: 1 set

5.5 Bearing seat (including bearing): 1 set Luoyang Bearing/Harbin Bearing

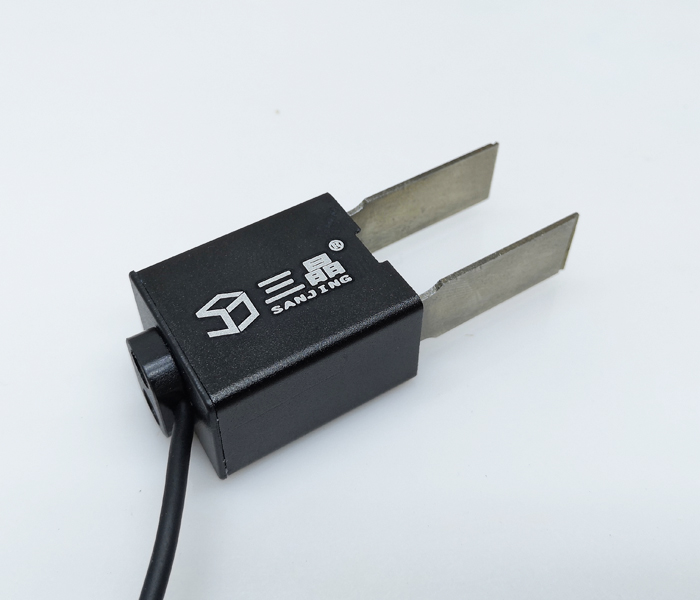

5.6 Controller:

5.7 Electrical system, 1 set of electrical control cabinet

5.8 Three-phase AC motor: 1 set in southern Anhui

5.9 Inverter: 1 Delixi

5.10 1 geared motor for space adjustment: Hangzhou

5.11 Lifting gear motor 1 set Wenzhou

5.12 Lubricating oil pipeline

5.13 1 set of random tools and test tooling

5.14 A copy of technical data

Related Items

Sales01

Sales01

Sales Manager

Sales Manager