Manual Rockwell hardness tester

Model: HR-150A

Description

The HR-150A Rockwell hardness tester features desk type, it adopts Rockwell testing principle, it’s suitable for hardness test of hard alloy, carbon steel, steel alloy, cast iron, nonferrous metal and many other materials, it’s widely used in many industrial area.

Features

a. Accurate testing result, reliable product, high testing efficiency

b. Dial gauge can read out HRA, HRB, HRC rule;

c. With precision oil buffer, adjustable loading speed d. Totally manual operation for testing process

e. Widely used in production field quality control, well-adapted for working condition

f. Complies to GB/T230.2 ISO 6508-2 and ASTM E18

Installation direction

Working condition:

a. Temperature of 10-30℃

b.≤65% relative humidity

c. Stable condition

d. No corrosive medium around

Un-boxing

a. Uninstall the 4 nuts at base, take out the accessories box

b. Back out the 2 M10 screws at base to make the tester be separated from the base, take out the hardness tester.

c. Place the tester on a stable working platform horizontally, the levelness error over than 1mm/m. open pore on table to make the screw can work normally.

Maintenance & Noted item

a. Operators should complies the operation rule to use the tester, should calibrate the tester with standard block regularly. For testers not frequently in using, operators should do several tests on standard block until the results are stable.

b. The tester should be carried in bottom, and can’t be carried in horizontally, should take out the weights and suspender.

c. When loading testing force/keep testing force/unloading testing force, it’s strictly to rotate the loading-variable hand-wheel.

d. The hardness block can only be used on working platform, the distance between neighbouring impresses, and the impress center to the border can’t be less than 3mm, the working period is 2years.

e. Calibrate the tester regularly, do calibration at least 1 time to guarantee the precision.

f. If there is error occurred with tester, please contact the supplier for trouble-shooting.

Specifications:

a. Testing range: 20-88HRA, 20-100HRB, 20-70HRC

b. Testing force: 588.4, 980.7, 1471N

c. Sample allowed max height: 170mm

d. Pressure head to wall distance: 135mm

e. Hardness resolution: 0.5HR

f. Overall size: 466 x 238 x 630mm

Weight: Approx 65kgs

Main accessories:

a. Big flat platform: 1no

b. Small flat platform: 1 no

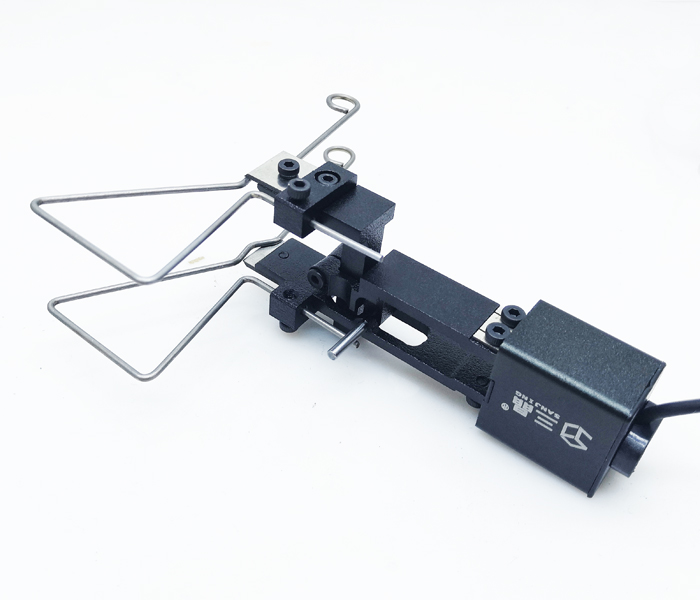

c. V shape testing platform: 1 no

d. Diamond conical pressure head: 1no

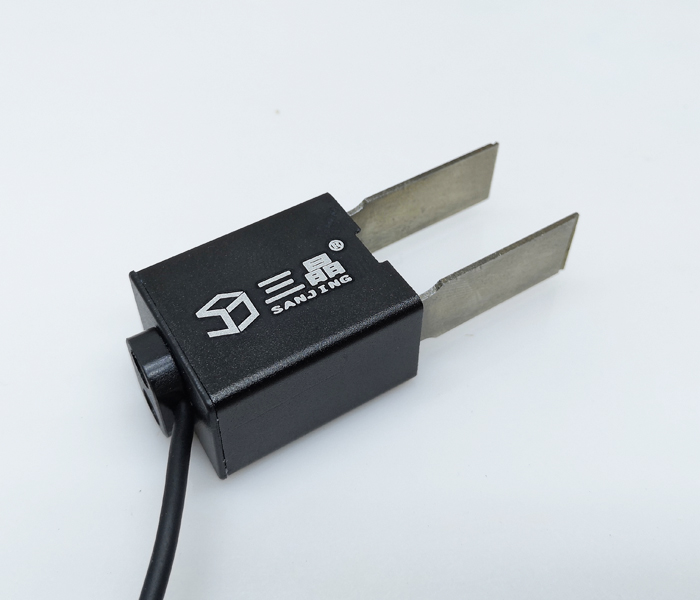

e.1/16” steel ball pressure head: 1 no

f. Standard Rockwell hardness block: 5pcs

Related Items

Sales01

Sales01

Sales Manager

Sales Manager