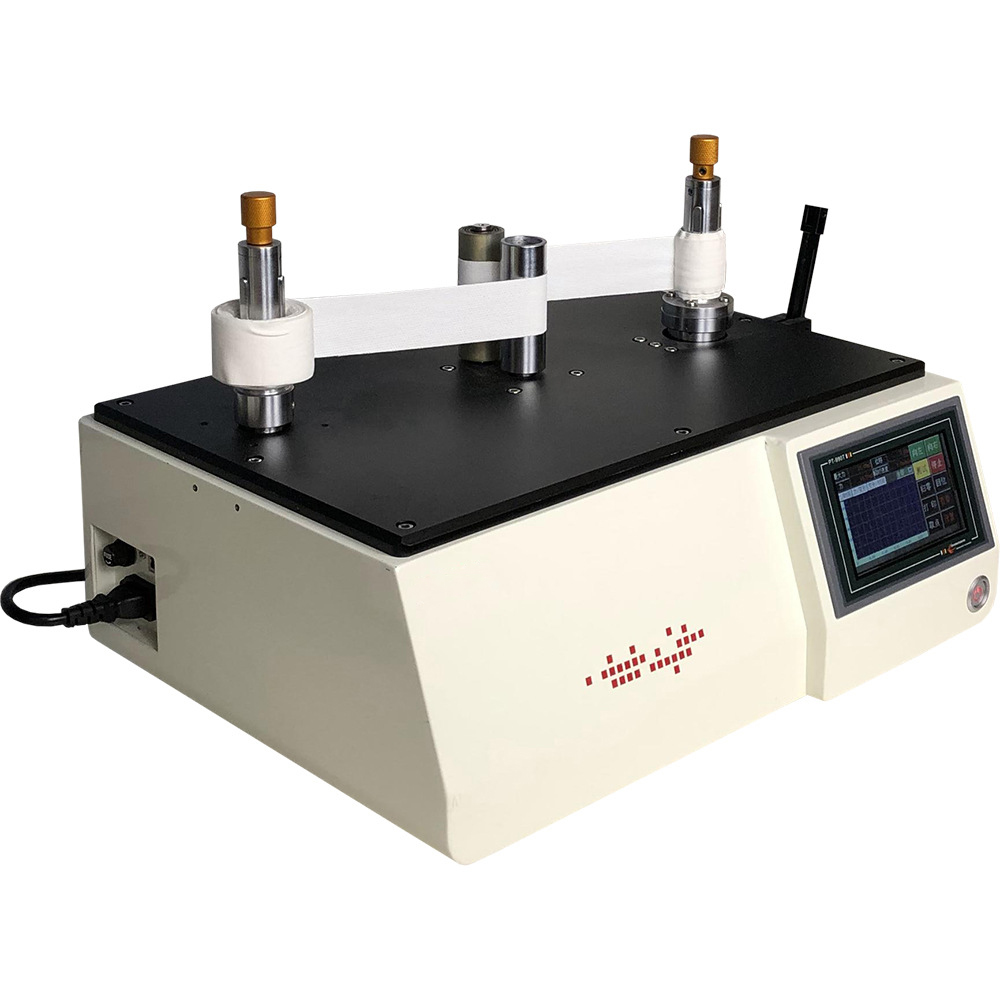

Low temperature brittleness tester ASTM-D746 JIS K7216

Model: SX-DWC01

Standards

GB/T 15256-2014 Determination of low temperature brittleness of vulcanized rubber (multi-sample method)

ASTM D2137-2010 Flexible polymer and its coating fabric embrittlement point test method

GB/T5470-2008 Determination of Embrittlement Temperature of Plastic Impact Method

ASTM D746-2007 Test Method for Determining the Embrittlement Temperature of Plastics and Elastic Materials by Impact Method

GB/T 12584-2008 Rubber or plastic coated fabric Low temperature impact test

JIS K7216-1980 Test method for low temperature embrittlement of plastics

JIS K6261-2006 Vulcanized or thermoplastic rubber–Determination of low temperature characteristics

ISO 812-2006 Vulcanized rubber or thermoplastic rubber–Determination of low-temperature brittleness

ISO 974-2000 Plastics. Determination of brittleness temperature by impact method

This testing machine is used to determine the brittleness temperature of non-hard plastics by Cantilever hammer impact test method. It can determine the impact embrittlement temperature and impact embrittlement threshold temperature when the damage degree reaches 50%.

Specifications

| Volume & Weight |

| 1.1. Test trough size |

18×57×15 cm |

| 1.2. Machine dimensions |

75×90×145 cm |

| 1.3. Net weight |

180kg |

| 2. Specifications |

|

| 2.1. Environment condition |

The ambient temperature is +25℃, and the relative humidity is ≤85%. |

| 2.2. Test standards |

GB/T 15256-2014 Determination of low temperature brittleness of vulcanized rubber (multi-sample method)

ASTM D2137-2010 Flexible polymer and its coating fabric embrittlement point test method

GB/T5470-2008 Determination of Embrittlement Temperature of Plastic Impact Method

ASTM D746-2007 Test Method for Determining the Embrittlement Temperature of Plastics and Elastic Materials by Impact Method

GB/T 12584-2008 Rubber or plastic coated fabric Low temperature impact test

JIS K7216-1980 Test method for low temperature embrittlement of plastics

JIS K6261-2006 Vulcanized or thermoplastic rubber–Determination of low temperature characteristics

ISO 812-2006 Vulcanized rubber or thermoplastic rubber–Determination of low-temperature brittleness

ISO 974-2000 Plastics. Determination of brittleness temperature by impact method |

| 2.3. Temp. range |

RT℃~-76℃(Room temp. 25℃)

|

| 2.3.1. Temp. fluctuation |

≤±0.5℃ |

| 2.3.2. Temp. deviation |

≤±2.0℃ |

| 2.3.3. Temp. drop rate |

RT→-76℃ ≤80min (average in full scale)– Mechanical refrigeration |

| 2.3.4. Impact edge radius |

1.6mm±0.1mm |

| 2.3.5. Impact rate |

1.4—2.4m/sec(adjustable)digital display 0.0m/sec

200±20cm/s speed unchanged within 6mm range after impact

|

| 2.3.6. Sample loading quantity |

A type 15pcs*4 groups, B type 4groups*5pcs

|

| 2.3.7. Sample size |

Sample A: L20±0.25mm* W2.5±0.05mm*T2.0±0.1mm

Sample B: L31.75±6.35mm W6.35±0.51mm T1.91±0.13mm |

| 2.3.8. Clearance between impact head centerline and fixture |

A Clamp 3.6mm±0.1mm B Clamp 6.4±0.3 mm |

| 2.3.9. Clearance between the outside of the impact head and the fixture |

A clamp 2.0mm±0.1mm B clamp 8.0±0.3mm |

| 2.3.10. Jaw radius |

4.0mm±0.1mm(A Clamp) |

| 2.3.11. Sample soaking time |

5+0.5/-0 min or 3min+0.5/-0 min |

| 2.3.12. Heat tube |

1.5kw |

| 3. Operation requirements |

| 3.1. Installation site |

The ground is level and well ventilated

No strong vibration around the equipment

no strong electromagnetic field around the equipment

No flammable, explosive, corrosive substances and dust around the equipment

There is a drainage floor drain near the equipment

Ground load-bearing capacity of the site: not less than 800kg/m2

Leave proper use and maintenance space around the equipment. |

| 3.2. Ambient Conditions |

Temp.:15℃~35℃

Relative humidity:≤85%

Air pressure:86kPa~106kPa |

| 3.3. Electricity supply

|

AC380V three-phase four-wire + protective ground wire

Allowable voltage fluctuation range: AC (380±38) V

Allowable frequency fluctuation range: (50±0.5) Hz

The grounding resistance of the protective earth wire is less than 4Ω; TN-S power supply or TT power supply

The user is required to configure an air or power switch with the corresponding capacity for the equipment at the installation site, and this switch must be independent for the use of the equipment

Total power: 5kW

Maximum current 20A |

| 3.4. 3-D graph |

|

Related Items

Sales01

Sales01

Sales Manager

Sales Manager